Interacting with the Rover using Simulink

our other blogs

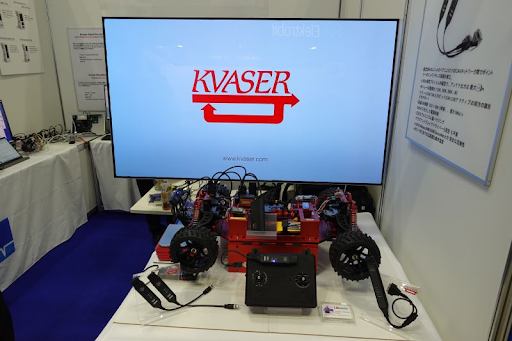

CanEduDev formally partners with Kvaser

As a newly appointed Technical Associate to Kvaser, CanEduDev is set to bring its Rover platform to the forefront of CAN technology demonstrations and education. This collaboration underscores our sh...

read moreCanEduDev Rover: Progress Report on System Integration and Architecture

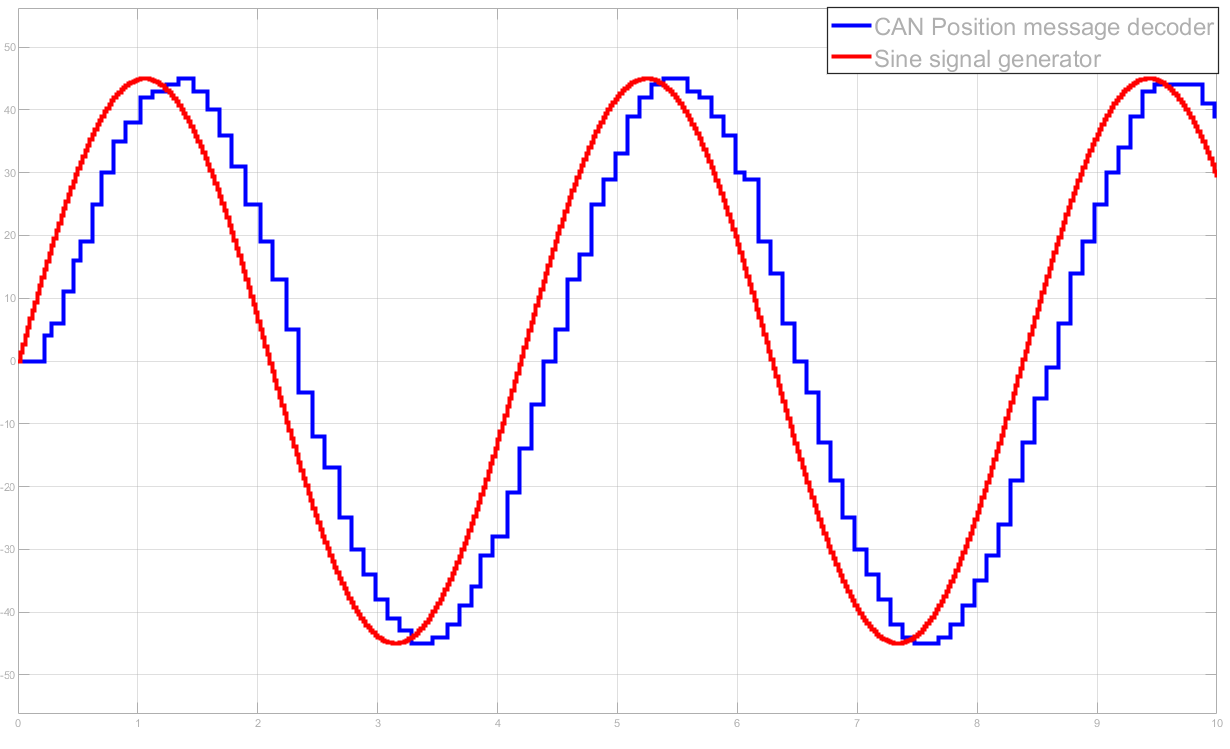

CanEduDev Rover: Technical Progress Update on System Integration We are excited to share a detailed update on the ongoing development of the CanEduDev Rover, a key project within our collaboration wi...

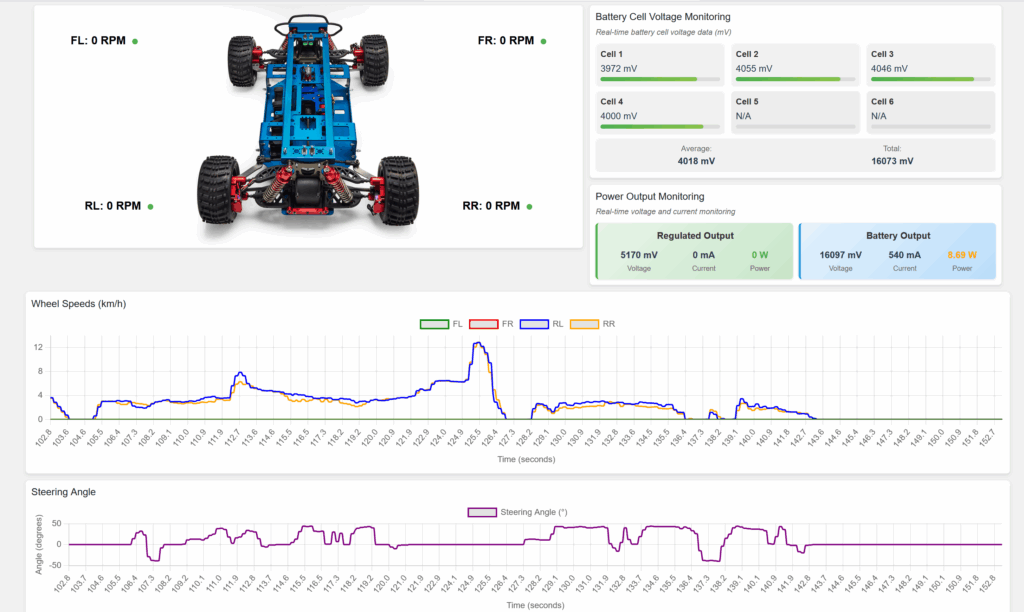

read moreCase Study: How Influx’s Use of the CanEduDev Rover Platform is Accelerating Automotive Development and Demo Capabilities

Case Study: How Influx's Use of the CanEduDev Rover Platform is Accelerating Automotive Development and Demo Capabilities Executive Summary Influx Technology is leveraging the CanEduDev Rover platfo...

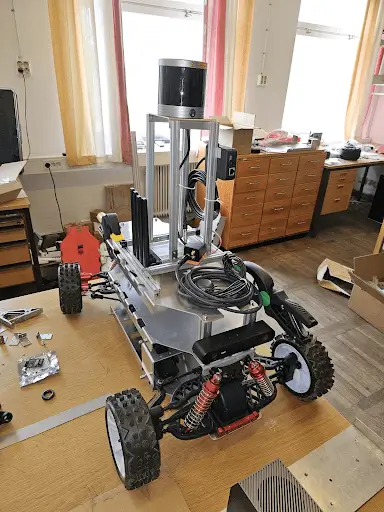

read moreHow LiU Formula Student Is Using the CanEduDev Rover to Drive Autonomous Innovation

At Linköping University, the Formula Student Driverless Team has taken on the challenge of building an advanced autonomous vehicle platform. To accelerate their development and testing processes, the...

read moreCAN-ROS Integration: What Auto & Industry Need to Know

As someone working in automotive and industrial automation, you've likely faced this dilemma: How do we leverage modern robotics frameworks without compromising the real-time guarantees our systems re...

read moreBringing Autonomy to Life: Autoware Integration with the CanEduDev Rover

In Alex Carballo’s lab at Gifu University, cutting-edge research and hands-on robotics come together to create innovative solutions. In their latest project, headed by Tomoki Kuno, they showcase th...

read more